Okay y’all sometimes you have a beautiful piece of furniture from the beginning… and sometimes you have to work for it. This was definitely one of those “have to work for it” kind of times. My Mom actually picked up this buffet and then asked “you know how to repair veneer right?!”

Luckily I do know how to repair veneer… unluckily this piece took several days to fix and Mom’s not quite as handy with the camera as I would like… so you’ll have to hang in there through some of these photos.

There’s a realllllly good one of me painting the fixed veneer late late at night that you just won’t want to miss!

We wouldn’t want to skip ahead though… let’s start at the beginning.

Step 1: Start by Cleaning!

This piece was just a little moldy after sitting outside for quite a while so the very first step was to clean the entire piece. Wipe it down with soap and water before wiping this baby down with a lint free rag.

Since the bottom has quite a bit of broken veneer we decided to stain the top and paint the bottom. A neutral white chalk paint with a bit of good old fashioned distressing (I stuck with my absolute favorite: linen white by Rust-Oleum). It should go beautifully with a dark walnut stained top.

Since the veneer would be the hardest part to fix we started with the top.

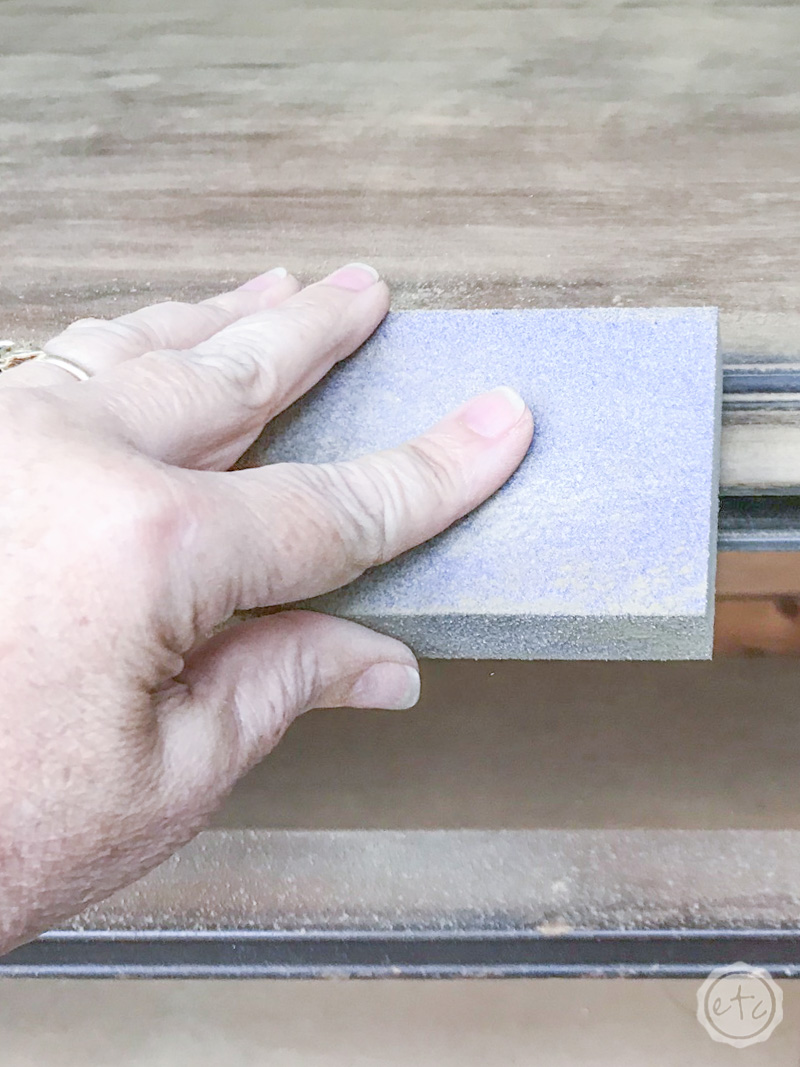

Sanding the uneven finish down so that we could re-stain the surface.

Step 2: Time to Sand and Stain the Surface

Since we’re re-staining the surface with a similar color to the original stain (in this case Minwax Dark Walnut) we don’t have to sand the surface allllllll the way down to the bare bones but simply sand the sealer off and the surface smooth. It was finished with different sealers that needed to be removed before it could be re-stained… so once the sealer is removed and the little nooks and cranny’s are clear we’re good to re-stain this baby.

Of course, if we were trying to re-stain the top with a lighter color we would have to keep going with the sanding but in this case the colors are so close they’ll bend together.

Score!

Now that our surface is free of sealer we can go ahead and re-stain the top. Once it’s stained it’s easy enough to seal the entire surface! Easy peezy.

Light layers of sealer y’all… layer of sealer, sand, layer of sealer, sand, layer of sealer. Repeat until the surface is smooth.

Step 3: Time to Fix the Veneer!

Just take a look at allllll that chipped veneer. Icky icky. Since the veneer is already chipping off we have two options for the edges… finish taking it off or glue it back on. Large pieces that can be glued and clamped are fine but anything smaller and jagged that’s still loose can come off.

Just be sure not to make a bigger mess… if you’re not able to take the peeling veneer off without it flaking even more use an exacto knife to remove the bigger chipping pieces.

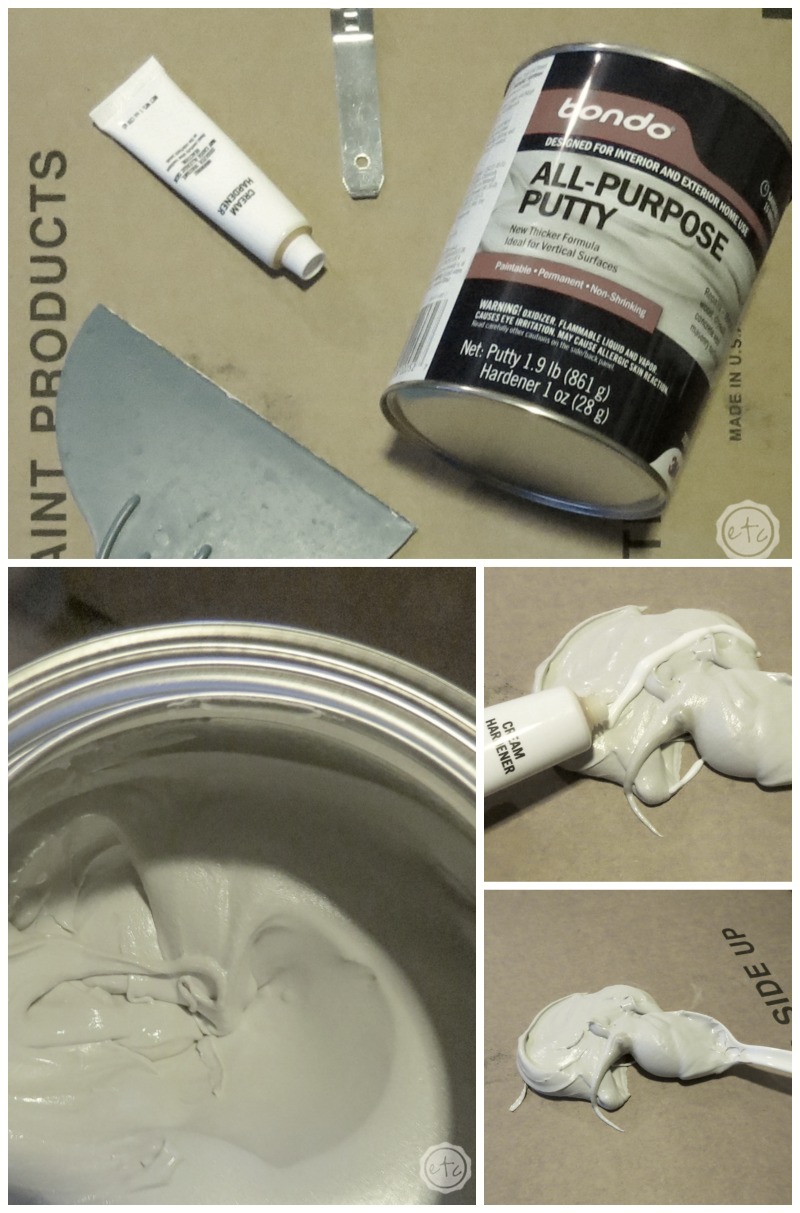

Once the veneer is done being… chippy… it’s time to fill in the pieces. Bondo is the perfect solution… it’s like wood putty except it dries hard.

Like concrete hard.

Luckily it’s easy to use but un-luckily it dries reallllllllyyyy fast so you can’t move slow. It’s a two part formula so only mix small bits so that you don’t have an entire brick worth of dried bondo before the story is over.

I’ve put together a little Bondo mixing collage for you… basically the steps are simple. A spoon full of bondo on a flat surface with a spoon you don’t mind throwing away… preferably a disposable one. Then take your tube of part B and add just a bit to your Bondo (I simply draw a line across the spoonful… it’s not an exact science but luckily it doesn’t have to be).

Now mix it all together and get ready to move.

You’ll apply the Bondo to your piece just like it was a nail hole in a wall you’re trying to spackle. Add a blob of Bondo to the chippy veneer area and then use your putty knife to smooth it out. Remember that at the end of the day you’ll be able to sand the surface smooth once the Bondo dries so more is better than less but at the end of the day you’re creating the illusion that the sideboard is whole so you’ll want the side to be even.

Bondo dries in less than 10 minutes so mix small amounts if you have a large piece to work on. Once the Bondo is applied the package says you can sand it in about 15 minutes but I’m always an overachiever so I like to wait about an hour.

Just in case.

Once the Bondo dries go ahead and sand the surface smooth. If there are still divots in the surface apply a second coat of Bondo until the surface is back to one piece. Perfecto!

Step 4: On to the Paint

Now that the Bondo is dry it’s time to paint the entire piece… which if you’re me is done at 1 in the morning on the front porch.

Which makes for reallllllyyyyy flattering photos!

Luckily I live in Alabama and chalk paint dries quickly here (even at 1 in the morning!) So I was able to put two coats of Rust-Oleum linen white on this baby in no time flat. This buffet didn’t have too many hidden nooks and crannies to paint so I stuck with a standard 2″ purdy brush and the paint went on like butter.

Now that we’re finished with the piece are you ready for the after pictures? This little buffet took so many days to finish (mainly because the Bondo just kept drying… making me re-mix spoonfuls at a time!).

Of course, I’d like to say this little piece was going in my home but as you know I’m in between houses at the moment… so this little gal is going over to the antique booth with all the other pieces I’ve painted lately.

I hope someone loves it as much as I do!

[…] recently spent a little time restoring the veneer on an old buffet… it took a couple days but when the buffet was finally pieced back together and painted a new […]